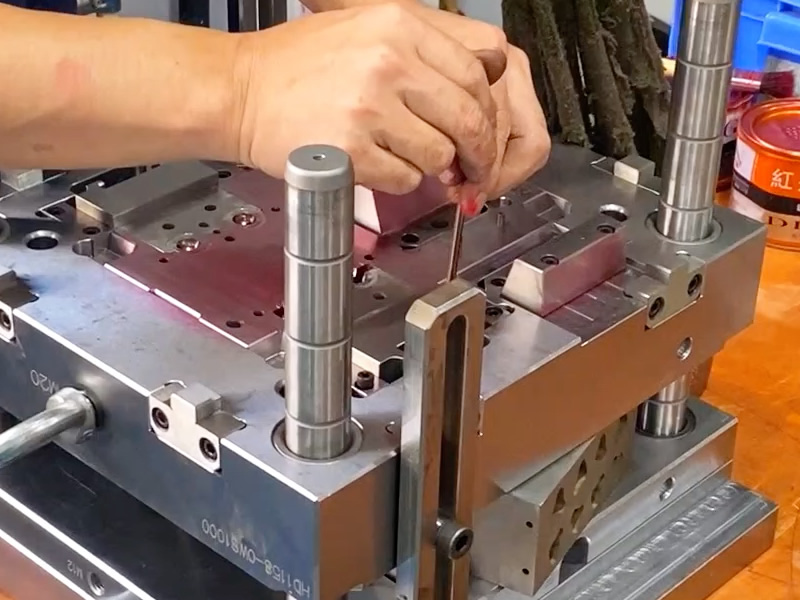

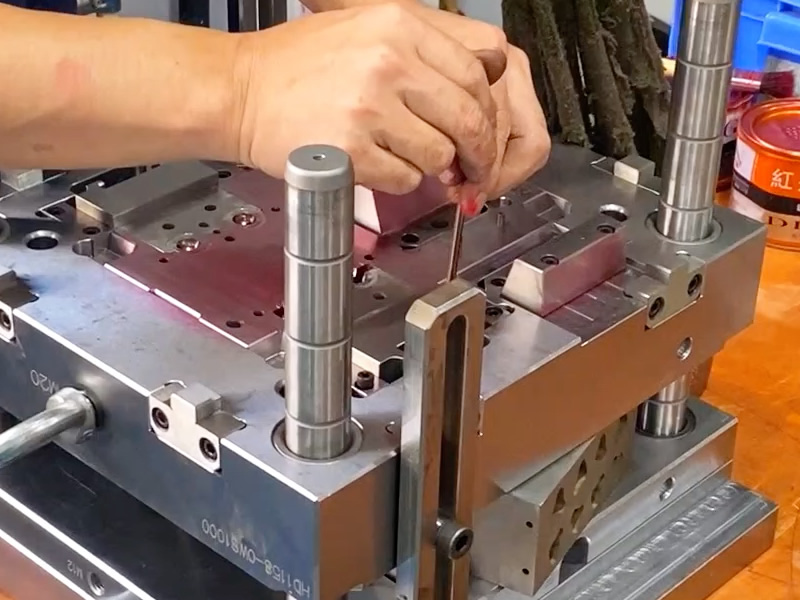

Mould

Date:2025-03-03 Click:1203

Molds are various molds and tools used in industrial production to obtain desired products through injection molding, blow molding, extrusion, die-casting or forging, smelting, stamping, and other methods. In short, a mold is a tool used to make molded objects, which is composed of various parts, and different molds are composed of different parts. It mainly achieves the processing of the shape of the object by changing the physical state of the formed material. Known as the 'Mother of Industry'.

A tool that transforms a blank into a specific shape and size of a workpiece under external force. Widely used in punching, forging, cold heading, extrusion, powder metallurgy parts pressing, pressure casting, as well as in the molding or injection molding of engineering plastics, rubber, ceramics and other products. The mold has a specific contour or inner cavity shape, and using a contour shape with a cutting edge can cause the blank to separate (punch) according to the contour line shape. The application of inner cavity shape can enable the blank to obtain a corresponding three-dimensional shape. A mold generally consists of two parts: a moving mold and a fixed mold (or a convex mold and a concave mold), which can be separated or combined. Remove the parts when separated, and inject the blank into the mold cavity to form when closed. Molds are precision tools with complex shapes that can withstand the swelling force of raw materials. They have high requirements for structural strength, stiffness, surface hardness, surface roughness, and processing accuracy. The development level of mold production is one of the important indicators of the level of mechanical manufacturing.